![]() Product

Seawater Electro-Hypochlorination System

Product

Seawater Electro-Hypochlorination System

Product

Efficient production facilities which is optimized for customer needs

Introduce GEUMHWA WTS’s product

Seawater Electro-Hypochlorination System

Seawater Electro-Hypochlorination System

More and more engineering and purchasing managers have discovered a way to eliminate the difficulty in handling and storage of chlorine gas. GEUMHWA WTS's long experience has helped them achieve a solution to these problems by supplying the Seawater Electro - Hypochlorination System.

GEUMHWA WTS’s System Advantages

- 01Optimum system design

- 02High efficiency cell module

- 03Concern for safety - no chlorine gas

- 04Long term reliability (Electrode life >5 years)

- 05Vast experience

Major Equipment

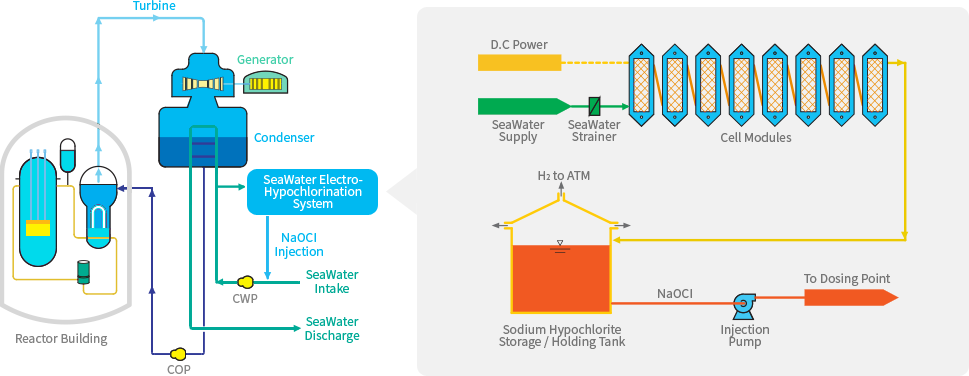

The Seawater Electro-Hypochlorination System is comprised of the following major equipment:

- - Sodium hypochlorite generators (SANILECE® cell modules)

- - Rectifies

- - Seawater supply pumps

- - Seawater strainers

- - Sodium hypochlorite storage / holding tanks

- - Sodium hypochlorite injection pumps

- - Diffusers

- - Piping, fitting & valves

- - Instruments & control panel

- - Seawater pretreatment system (if required)

Principle of Operation

In a typical Seawater Electro-Hypochlorination System, seawater is fed through a strainer, where particles are removed. From this point the seawater is fed to the electrolysis module by way of a flow controller. In the module, passage of direct current through the seawater converts a portion of the salt to hypochlorite by the following reaction:

NaCl + H2O + 2e --> NaOCl + H2↑

Applications

disengaging/product storage tank at the tank, the hydrogen gas is separated and vented then, the sodium hypochlorite solution is transferred and injected into the points required. Due to impurities in seawater, the cells are cleaned periodically to remove deposits on the electrodes.

- - Cooling water systems : Nuclear power plants, Thermal power plants, Combined cycle power plants, Desalination plants

- - Evaporation systems : LNG receiving terminals